Protect Your Cold Storage from Ammonia Leakage Hazards with the Yiyuntian Eranntex Ammonia Gas Detector and Alarm

Amid the rapid expansion of the food cold chain industry, ammonia refrigeration systems remain the mainstream choice for cold storage due to their high efficiency and cost-effectiveness. However, ammonia's inherent physical and chemical properties—flammability, explosiveness, strong irritancy, and high toxicity—permanently accompany refrigeration processes. Any leakage can trigger fires or explosions, posing severe threats to the health and safety of on-site personnel.

Addressing this industry challenge, Binglun Environmental Technology Co., Ltd. has embraced the mission of technological innovation. With safety as its core principle, the company has proactively integrated the Yiyuntian Eranntex Ammonia Gas Detector and Alarm system as a critical component of its cold storage safety framework. Through high-precision monitoring and intelligent interlocking, this system builds an impenetrable safety barrier for cold chain production, leading the industry toward greater safety and reliability.

I. Solution Background

In China's food freezing systems, over 80% of cold storage facilities utilize ammonia as a refrigerant. With technological advancements and the establishment of comprehensive regulatory frameworks, safety requirements for food cold storage have become increasingly stringent. Consequently, the safety of ammonia refrigeration systems in food cold storage has emerged as a critical issue in cold storage engineering. To prevent and mitigate ammonia leakage hazards while safeguarding personnel and property, greater emphasis is placed on rationally designing automatic ammonia leak alarm systems for ammonia refrigeration rooms during cold storage design. This ensures operational safety in ammonia refrigeration facilities.

Ammonia leakage poses a unique hazard in ammonia-based cold storage. Fire risks are the primary concern during leaks. Ammonia concentrations between 15.5% and 27% can explode upon contact with open flames. Furthermore, ammonia's inherent toxicity poses severe health risks to humans, causing convulsions, unconsciousness, and even fatal asphyxiation.

Numerous factors contribute to ammonia leaks in cold storage facilities, primarily including equipment aging, operational errors, and management negligence. As equipment ages over extended service periods, various forms of deterioration emerge. Valve aging and loosened shafts compromise gas tightness, leading to ammonia leakage. Welded joints in refrigeration pipes may also deteriorate, developing cracks, or pipes may corrode, and flanges may age, all contributing to leaks. Improper operator actions can cause ammonia leaks. If liquid ammonia or equipment oil enters the compressor cylinder due to operator error, excessive internal pressure may force the cylinder head off, resulting in a leak. Improper stacking of goods during loading/unloading can cause items to freeze solid and collapse suddenly, fracturing evaporator pipes and releasing gas. During loading/unloading, forklifts operating inside cold storage rooms may accidentally sever wall-mounted evaporator pipes, causing leaks. If workers mistakenly close valves on the section between the compressor and condenser during normal compressor operation, that pipeline segment may rupture.

II. Solutions

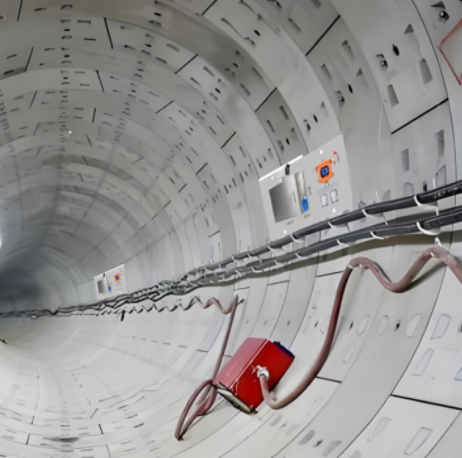

Monitoring Locations: Liquid ammonia storage tank areas in cold storage, refrigeration equipment assembly workshops, loading/unloading sites, ammonia gas transmission pipelines

Monitored Gas: Ammonia

Data Transmission: Based on the actual conditions of the cold storage site, ammonia detection alarms are installed at each monitoring location. In the event of an ammonia leak, the detected ammonia concentration data is transmitted to the controller in real time via electrical signal or wireless transmission. This triggers the gas shut-off valve to immediately cut off the gas supply source, activates the on-site ventilation system to rapidly disperse toxic gases, and ensures the safe operation of personnel and equipment.

III. Product Configuration:

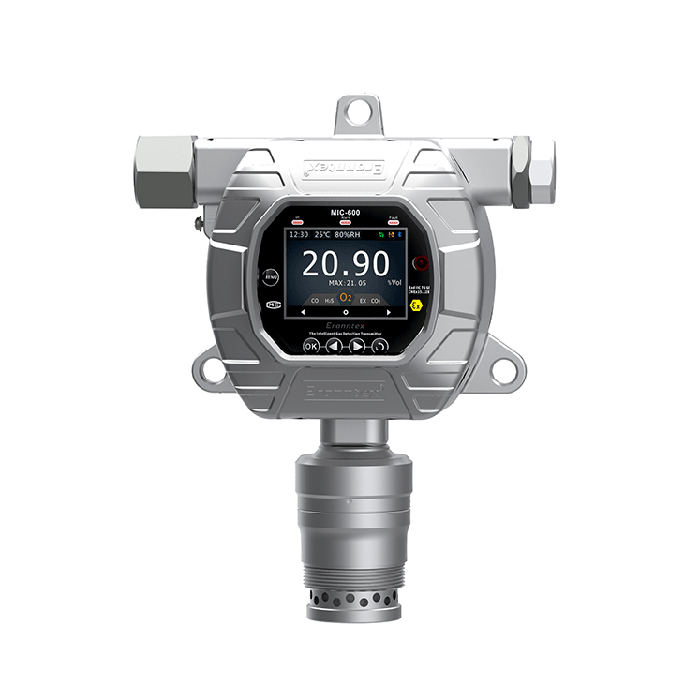

Product Name: Online Ammonia Gas Detection Alarm

Model: MIC-600-NH2-A-X

Detection Range: 0-500 ppm | Resolution: 0.1 ppm

Features: Imported electrochemical sensor

Controller Model: MIC200

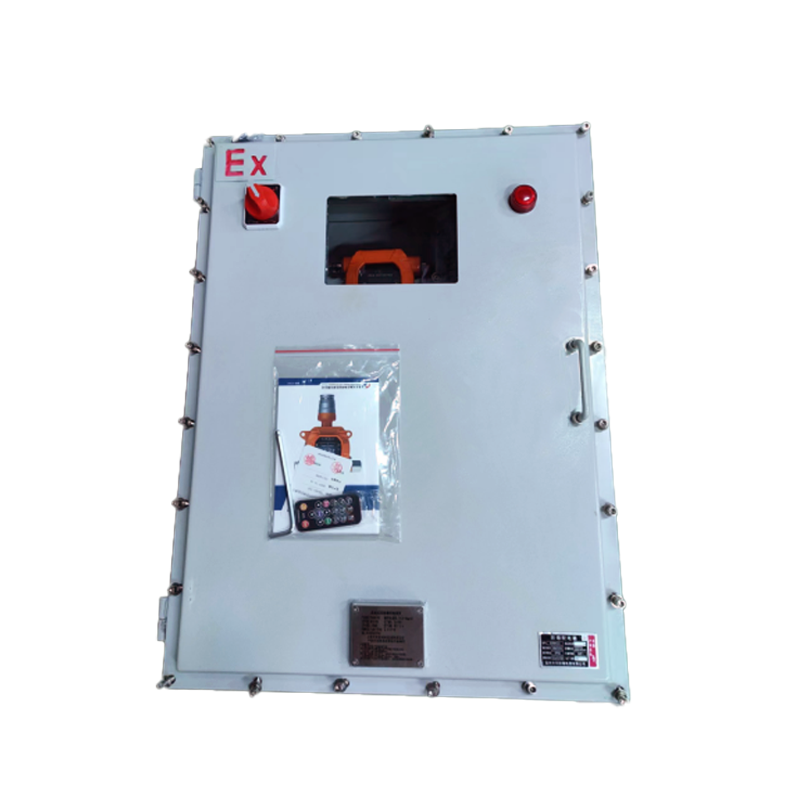

On-site product images are shown below:

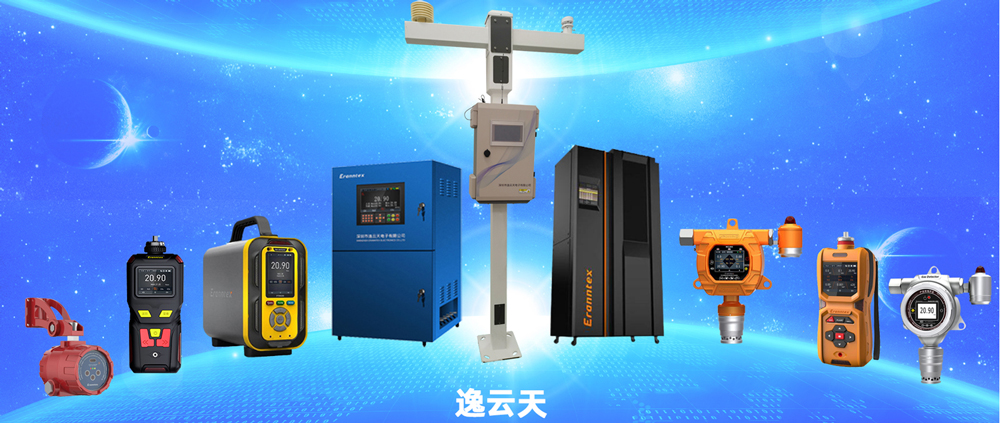

Through comprehensive deployment of Yiyuntian Eranntex ammonia detection alarms, Binglun Environmental Co., Ltd. has successfully established an intelligent ammonia leak prevention network covering all cold storage scenarios. From source monitoring at liquid ammonia storage tank areas, to process protection in refrigeration equipment workshops, to end-point safeguarding at loading/unloading sites and transmission pipelines, real-time ammonia concentration sensing and precise early warning are achieved at every critical node. Upon detecting leakage risks, the system instantly activates gas shut-off valves and ventilation systems to contain hazards at their source. This approach secures critical evacuation time for personnel while ensuring continuous, stable operation of refrigeration equipment. This innovative practice not only significantly enhances cold storage safety management efficiency and reliability but also sets an industry benchmark for “technology-driven safety.”

Within this comprehensive intelligent prevention and control network, the Yiyuntian Eranntex ammonia gas detector and alarm fully demonstrates its formidable strength as an industry-leading brand. Moving forward, Yiyuntian Eranntex will remain steadfast in its pursuit of excellence and deep industry insights. With an unwavering commitment to precision and focus, it will thoroughly explore the safety requirements of the cold chain sector. Leveraging advanced technology and extensive experience, Yiyuntian Eranntex will deliver tailored safety solutions for the cold chain industry. This will empower food cold storage facilities to achieve an optimal balance between efficient production and robust safety measures, collectively advancing toward a greener, more sustainable future.

Related information

-

Yiyuntian Eranntex Valve Well Leak Detection Equipment Enables “Visible, Early Warning” Leak Monitoring for Urban Gas Pipelines

Urban gas pipeline networks serve as critical infrastructure for energy distribution, providing essential power to households, bus...

2025-12-15 -

Yiyuntian Eranntex Odor Online Monitoring System Emerges as a New Powerhouse for Environmental Enterprises

Within the modern framework of harmonizing industrial production with ecological conservation, workshop safety and environmental q...

2025-12-12 -

Protect Your Cold Storage from Ammonia Leakage Hazards with the Yiyuntian Eranntex Ammonia Gas Detector and Alarm

Amid the rapid expansion of the food cold chain industry, ammonia refrigeration systems remain the mainstream choice for cold stor...

2025-12-10 -

Yiyuntian Eranntex MS600-S2 Gas Detector Protects Every Gas Detection You Need

With the increasing complexity of industrial production and laboratory environments, the demand for accurate monitoring of environ...

2025-11-26 -

Yiyuntian Eranntex Portable Ammonia Detector Wins Market Trust with Solid Performance

Addressing this industry pain point, Yiyuntian Eranntex leveraged its deep technical expertise and profound understanding of custo...

2025-11-21

info@eranntexgas.com

info@eranntexgas.com

13480931872

13480931872