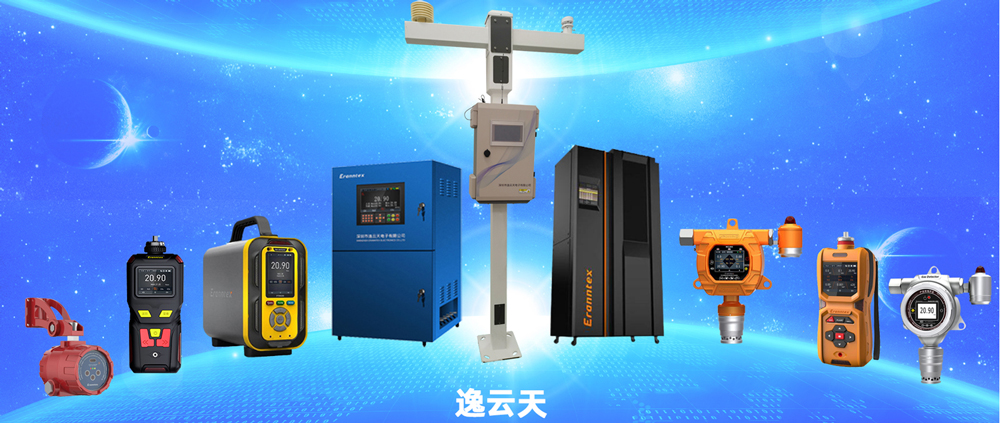

Yiyuntian Eranntex Odor Online Monitoring System Emerges as a New Powerhouse for Environmental Enterprises

Within the modern framework of harmonizing industrial production with ecological conservation, workshop safety and environmental quality form the cornerstone of sustainable corporate operations. The Nanning plant of a Guangxi-based environmental technology group has consistently prioritized safeguarding the surrounding ecosystem while maintaining production efficiency. Addressing the latent odor pollution in workshop operations and the plant premises has emerged as a critical challenge requiring focused solutions.

Odorous pollutants are complex in composition, encompassing nine substances including ammonia, hydrogen sulfide, and trimethylamine. These gases not only emit strong irritating odors that impact worker health and surrounding residents' quality of life, but their emission compliance directly determines whether enterprises meet national “Odorous Pollutant Emission Standards.” More critically, odorous gas concentrations fluctuate with production conditions and environmental factors, while some components pose significant hazards despite extremely low concentrations. Traditional monitoring methods struggle to achieve comprehensive, accurate detection across all dimensions. Therefore, real-time, continuous, and high-precision online monitoring of these nine odorous indicators is not merely a reactive measure to meet environmental regulations. It is an intrinsic necessity for enterprises to proactively manage pollution risks, safeguard operational safety, and protect brand reputation.

For this environmental technology group, investing resources in workshop and plant environmental management centers on achieving effective control and compliant discharge of malodorous pollutants. The efficacy of such management ultimately requires scientific, authoritative data to substantiate. This urgent need for comprehensive indicator coverage, low detection limits, and multi-scenario adaptability calls for a specialized online odor monitoring solution.

Against this backdrop, the Yiyuntian Eranntex TH-2000-OU Odor Online Monitoring System emerged as the core monitoring tool for enterprises safeguarding workshop and plant air quality while achieving compliant emissions.

1. Project Background

Nanning, Guangxi Odor Online Monitoring Project: Environmental testing within workshops and designated areas at the Nanning plant of XX Environmental Technology Group Co., Ltd.

2. Parameter Requirements

Compliance with the nine odor-related indicators specified in the national standard “Emission Standard for Odorous Pollutants (GB14554-1993)”, including ammonia, trimethylamine, hydrogen sulfide, methyl mercaptan, dimethyl sulfide, carbon disulfide, styrene, and odor gas.

Requirements:

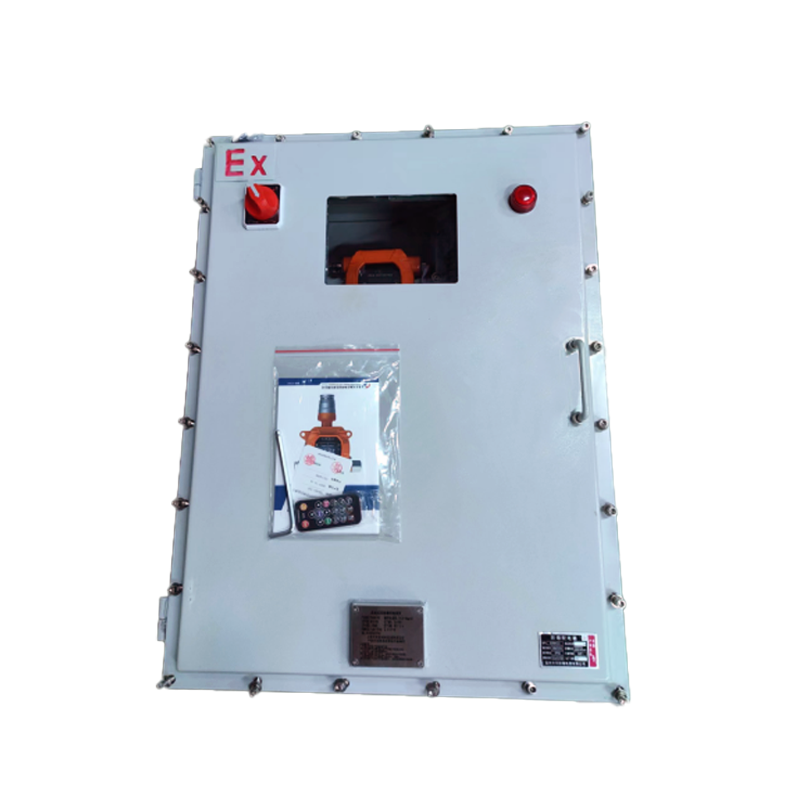

Equipped with audible and visual alarms; Industrial-grade high-precision touchscreen displaying current concentration values, maximum/minimum readings, 1-minute and 1-hour averages, with historical data query capability for any time period and curve visualization; Built-in high-capacity storage chip capable of storing over 100,000 data points, with dedicated interface for data export; Enclosure features outdoor-specific nano-protective coating technology, resistant to sun exposure, rain, heat, and insects, enabling long-term outdoor operation; Compatible with TCP/IP, MODBUS, DTU, and other communication protocols, supporting both wireless data upload to local environmental bureaus or cloud platforms and wired remote transmission networking.

Two sets for workshops, two sets for factory premises

3. Solution

Recommended parameter configuration:

Detected Gases: H₂S (Hydrogen Sulfide), NH₃ (Ammonia), C₃H₉N (Trimethylamine), CH₄S (Methyl Mercaptan), C₂SH₆ (Methyl Mercaptan), C₂H₆S₂ (Dimethyl Disulfide), C₈H₈ (Styrene), CS₂ (Carbon Disulfide), OU

H₂S: Detection range 0-100ppm, resolution 0.01ppm

NH₃: Detection range 0-100ppm, resolution 0.01ppm

C₃H₉N: Detection range 0-20ppm, resolution 0.001ppm

CH₄S: Detection range 0-20 ppm, resolution 0.001 ppm

C₂H₆S: Detection range 0-20 ppm, resolution 0.001 ppm

C₂H₆S₂: Detection range 0-20 ppm, resolution 0.001 ppm

C8H8: Measurement range 0-20ppm, resolution 0.001ppm

CS2: Measurement range 0-20ppm, resolution 0.001ppm

OU: Measurement range 0-2000, resolution 1

4. Product Matching

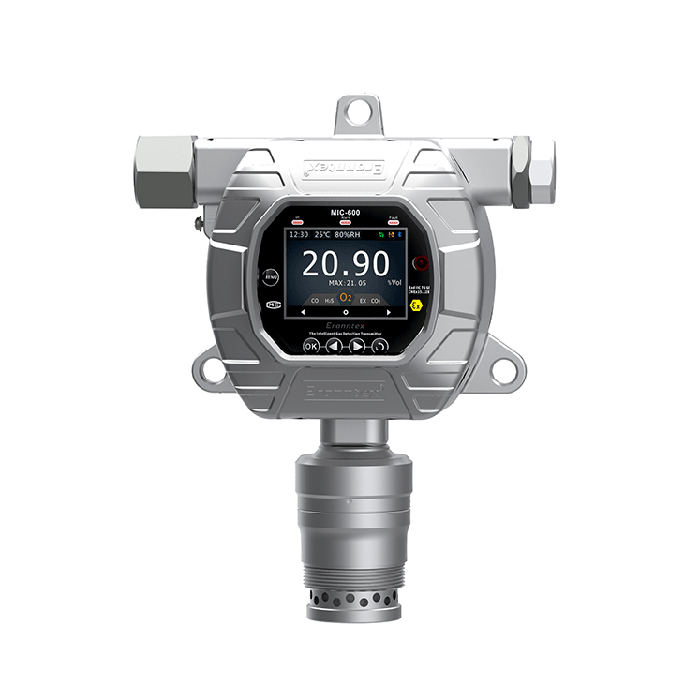

TH-2000-OU

Detected Gases: H₂S (Hydrogen sulfide), NH₃ (Ammonia), C₃H₉N (Trimethylamine), CH₄S (Methyl mercaptan), C₂H₆S (Methyl sulfide), C₂H₆S₂ (dimethyl disulfide), C₈H₈ (styrene), CS₂ (carbon disulfide), OU

H₂S: Detection range 0-100 ppm, resolution 0.01 ppm

NH₃: Detection range 0-100 ppm, resolution 0.01 ppm

C3H9N: Detection range 0-20ppm, resolution 0.001ppm

CH4S: Detection range 0-20ppm, resolution 0.001ppm

C2SH6: Detection range 0-20ppm, resolution 0.001ppm

C2H6S2: Detection range 0-20ppm, resolution 0.001ppm

C8H8: Detection range 0-20ppm, resolution 0.001ppm

CS2: Detection range 0-20ppm, resolution 0.001ppm

OU: Measurement range 0-2000, resolution 1

With the full deployment and stable operation of Yiyuntian Eranntex Electronics' online malodor monitoring system at the environmental technology group's Nanning plant, the enterprise has achieved dual enhancements in malodor pollution control and environmental compliance management. This monitoring system offers comprehensive detection capabilities across nine categories of malodorous indicators, featuring low detection limits. Paired with weather-resistant protection designed with outdoor-specific nano-coating, it builds a robust technological defense for workshop safety and plant environmental protection, serving as the data foundation for the enterprise's adherence to malodorous emission standards.

The implementation of this monitoring solution enables the enterprise to track real-time changes in malodorous gas concentrations within workshops and the entire facility. This provides robust evidence for pollution source tracing and treatment optimization, granting the enterprise a first-mover advantage in its environmental compliance strategy. Through the analysis and application of dynamic monitoring data, the enterprise successfully controlled malodorous emissions within national standards. This approach safeguards worker health and the quality of life for surrounding residents while contributing to regional ecological improvement. It not only enhances preparedness for future environmental policy upgrades but also establishes a commendable industry benchmark in pollution control.

For a certain environmental technology group in Nanning, Guangxi, this collaboration marks a pivotal step in upgrading its odorous pollution management from reactive measures to proactive prevention and precise control. This advancement equips the company with a technological edge in environmental compliance and ecological stewardship practices. For Yiyuntian Eranntex, this represents not only the successful implementation of an odor monitoring solution but also a significant advancement in comprehensive online monitoring of industrial odors. It reaffirms that Yiyuntian Eranntex monitoring technology can cover routine gas detection scenarios while meeting national standards for multi-component odor monitoring, playing a vital role in both corporate environmental governance and regional ecological protection.

Looking ahead, as environmental regulatory frameworks continue to evolve and corporate awareness of green development grows, the demand for comprehensive, low-detection-limit, round-the-clock odor pollution monitoring will become increasingly urgent. Yiyuntian Eranntex Electronics remains committed to its corporate mission of safeguarding the environment through technology. We will deepen our integration of odor monitoring technology with IoT and big data, continuously exploring multi-scenario adaptable odor control solutions. Yiyuntian Eranntex aspires to deliver smarter odor monitoring services across environmental protection, chemical, and municipal sectors through technological breakthroughs. By leveraging precise data and professional expertise, we aim to build robust ecological defense lines, safeguarding the fresh air and environmental harmony of every region.

Related information

-

Yiyuntian Eranntex Valve Well Leak Detection Equipment Enables “Visible, Early Warning” Leak Monitoring for Urban Gas Pipelines

Urban gas pipeline networks serve as critical infrastructure for energy distribution, providing essential power to households, bus...

2025-12-15 -

Yiyuntian Eranntex Odor Online Monitoring System Emerges as a New Powerhouse for Environmental Enterprises

Within the modern framework of harmonizing industrial production with ecological conservation, workshop safety and environmental q...

2025-12-12 -

Protect Your Cold Storage from Ammonia Leakage Hazards with the Yiyuntian Eranntex Ammonia Gas Detector and Alarm

Amid the rapid expansion of the food cold chain industry, ammonia refrigeration systems remain the mainstream choice for cold stor...

2025-12-10 -

Yiyuntian Eranntex MS600-S2 Gas Detector Protects Every Gas Detection You Need

With the increasing complexity of industrial production and laboratory environments, the demand for accurate monitoring of environ...

2025-11-26 -

Yiyuntian Eranntex Portable Ammonia Detector Wins Market Trust with Solid Performance

Addressing this industry pain point, Yiyuntian Eranntex leveraged its deep technical expertise and profound understanding of custo...

2025-11-21

info@eranntexgas.com

info@eranntexgas.com

13480931872

13480931872