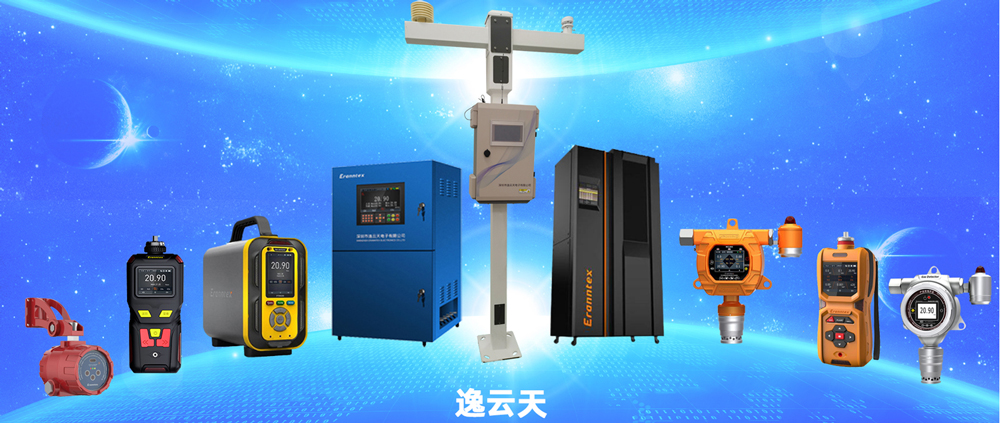

Constantly worried about gas hazards in your chemical plant? Yiyuntian Eranntex Weather gas detectors make safety visible!

In chemical production, particularly in the fine chemical manufacturing of chlorinated aromatic compounds (such as 2,6-dichlorocyanobenzene, o-chlorocyanobenzene, etc.) and their derivative products, gas safety serves as the “lifeline” throughout the entire production process. From raw material storage and transportation, through high-temperature and high-pressure processes in reactors, to product separation and purification, each stage carries the risk of flammable, explosive, toxic, or hazardous gas leaks due to equipment aging, operational errors, or environmental changes. These gases are not only highly toxic (e.g., hydrogen cyanide, chlorine gas), capable of causing rapid poisoning or death, but also highly flammable and explosive (e.g., benzene vapor, vinyl chloride). Once mixed with air to reach explosive limits, even minimal energy sources (e.g., static electricity, open flames) can trigger chain explosions, resulting in catastrophic consequences including plant destruction, casualties, and environmental pollution. Exceeding safe levels not only directly endangers lives but may also trigger secondary explosions from static electricity or open flames, leading to irreversible catastrophic consequences.

Pain Points of Traditional Management:

· Manual inspections are time-consuming: Relying on scheduled manual checks makes it difficult to cover continuous 24-hour production scenarios;

· Multi-gas monitoring challenges: Single devices cannot simultaneously detect multiple toxic/flammable gases, creating monitoring blind spots;

· Passive emergency response: Reliance on manual alerts after leaks occurs delays critical response windows;

· High compliance risks: Incomplete data logging from traditional equipment fails to meet the risk traceability requirements of the Work Safety Law.

Against this backdrop, Yiyuntian Eranntex Weather gas detectors establish an intelligent protection network spanning the entire “perception-decision-execution” chain through a millisecond-level response mechanism that triggers alerts upon exceeding thresholds. This upgrades traditional passive monitoring to proactive prevention, providing critical technological support for chemical enterprises to solve complex safety challenges involving multiple coexisting gases and overlapping risks.

1. Solution Background

The user, Hubei Nuosulai New Materials Co., Ltd., primarily manufactures 2,6-dichlorocyanobenzene, 3,4-dichlorocyanobenzene, o-chlorocyanobenzene, p-chlorocyanobenzene, m-dicyanobenzene and their derivative products, along with other chemical raw materials and products. Due to raw materials and production processes, chemical plants generate flammable, explosive, toxic, and hazardous gases during operations. These gases pose secondary hazards.

2. Solution

In industrial settings, gas detection equipment serves not only as a cornerstone of safety but also as a vital pillar for production efficiency and environmental protection. Let us explore why these devices are indispensable. From a safety perspective, industrial sites frequently involve the processing, storage, and discharge of various chemicals, which may release toxic, flammable, or explosive gases. Should concentrations of these gases exceed safe thresholds, they directly threaten personnel safety. Gas detectors monitor harmful gas levels in real time, triggering immediate alerts to prompt evacuation and corrective actions, effectively preventing accidents and safeguarding workers' lives.

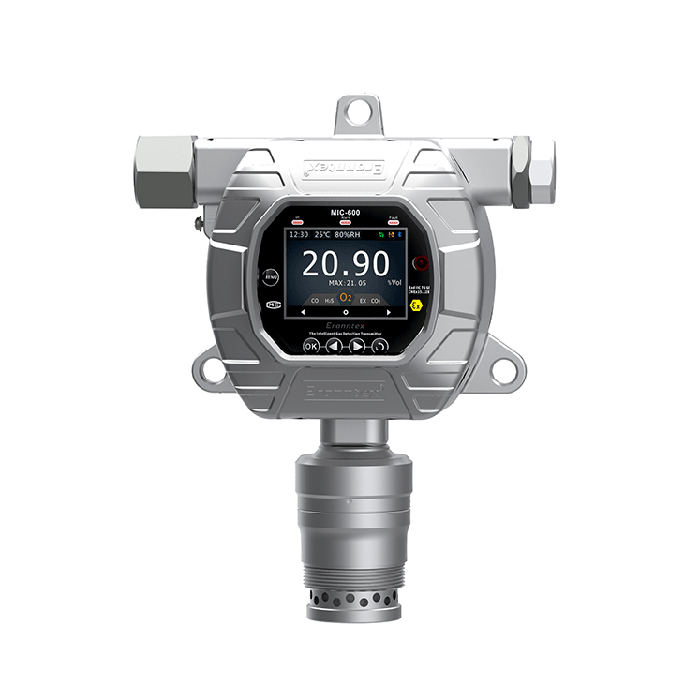

3. Compatible Products:

(1) Fixed Ammonia Gas Detector MIC-500S-NH3-A-I;

(2) Fixed Carbon Monoxide Detector MIC-500S-CO-A-I;

(3) Fixed Hydrogen Cyanide Detector MIC-500S-HCN-A-I;

(4) Fixed combustible gas detector MIC-500S-EX-A-I;

(5) Fixed oxygen detector MIC-500S-O2-A-I;

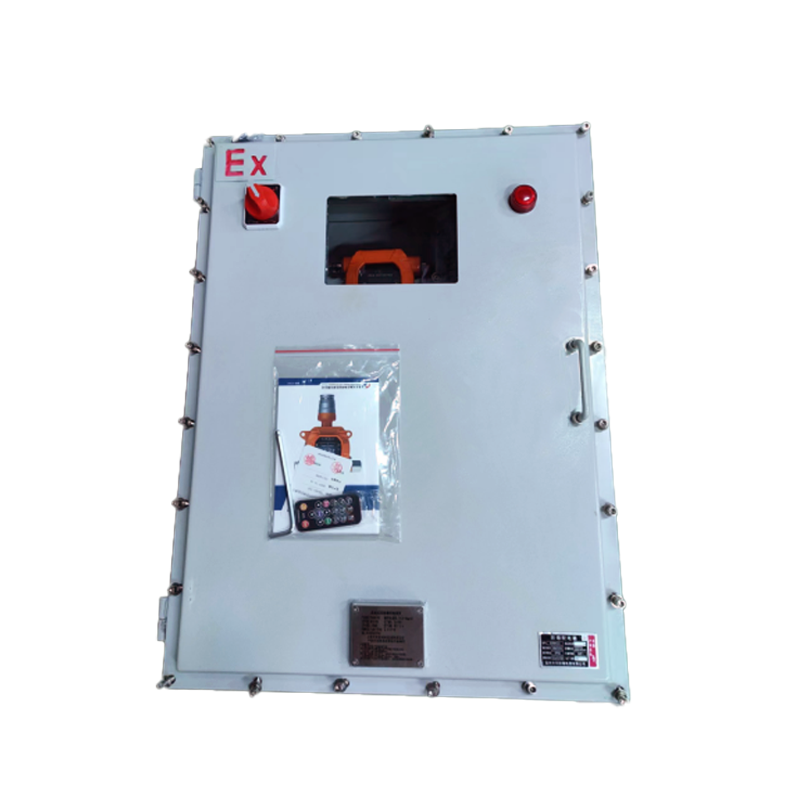

(6) Explosion-proof area audible/visual alarm lights

(7) Bus-based controller MIC3000

On-site product images are as follows:

Through comprehensive deployment of Yiyuntian Eranntex gas detectors, a multi-dimensional monitoring network has been established covering the entire process from raw material storage and production reactions to finished product transportation. From highly toxic chlorine gas and hydrogen cyanide to flammable and explosive benzene vapors and hydrogen gas, the equipment enables 24/7 precise detection. Should concentrations approach safety thresholds, it immediately triggers audible and visual alarms while activating ventilation systems and shut-off devices to eliminate risks at their inception. This system not only fortifies a lifesaving barrier for workers but also boosts production efficiency by over 20% through reduced unplanned downtime and material waste. Simultaneously, it lowers exhaust emissions, supporting enterprises in achieving green transformation goals.

The successful application of Yiyuntian Eranntex gas detectors not only validates its hard-core capabilities as an industry benchmark but also demonstrates the boundless potential of technology in empowering safety management. Moving forward, Yiyuntian Eranntex will continue to deepen its commitment to industrial safety, delivering smarter and more reliable gas monitoring solutions to accelerate the chemical industry's progress toward a safer, more efficient, and more sustainable future.

Related information

-

Failing compliance inspections? Yiyuntian Eranntex oxygen detectors ensure traceable data for enhanced compliance.

Amidst rising consumer expectations, demands for food freshness and safety have grown increasingly stringent. As a critical method...

2026-01-21 -

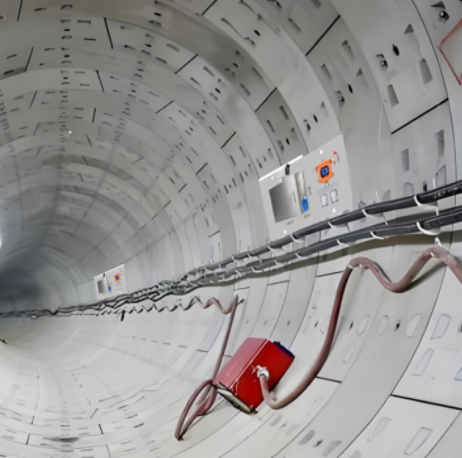

Yiyuntian Eranntex Wireless Integrated Gas Detection Solution Emerges as New Choice for Confined Space Protection!

Confined spaces are enclosed with poor ventilation, prone to accumulating gases like carbon dioxide and methane. They may also exp...

2026-01-20 -

Constantly worried about gas hazards in your chemical plant? Yiyuntian Eranntex Weather gas detectors make safety visible!

Against this backdrop, Yiyuntian Eranntex Weather gas detectors establish an intelligent protection network spanning the entire “...

2026-01-19 -

Yiyuntian Eranntex Valve Well Leak Detection Equipment Enables “Visible, Early Warning” Leak Monitoring for Urban Gas Pipelines

Urban gas pipeline networks serve as critical infrastructure for energy distribution, providing essential power to households, bus...

2025-12-15 -

Yiyuntian Eranntex Odor Online Monitoring System Emerges as a New Powerhouse for Environmental Enterprises

Within the modern framework of harmonizing industrial production with ecological conservation, workshop safety and environmental q...

2025-12-12

info@eranntexgas.com

info@eranntexgas.com

13480931872

13480931872