Yiyuntian Eranntex Wireless Integrated Gas Detection Solution Emerges as New Choice for Confined Space Protection!

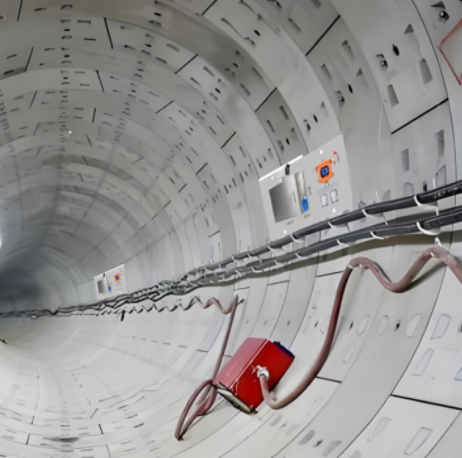

In modern shipbuilding systems, confined space operations at shipyards constitute a critical production process. These operations span multiple scenarios—including ship compartments, pipelines, and enclosed chambers—directly impacting vessel construction progress and quality. Shanghai XX Shipyard consistently prioritizes personnel safety in advancing production operations. However, the unique environment of confined spaces harbors significant safety risks that cannot be overlooked.

Confined spaces are enclosed with poor ventilation, prone to accumulating gases like carbon dioxide and methane. They may also experience oxygen deficiency, VOC overexposure, and particularly the highly toxic hydrogen sulfide. Abnormal gas concentrations directly threaten worker safety. More critically, real-time linkage between worker locations and gas hazards is essential for comprehensive prevention. Traditional detection methods struggle to meet requirements for wireless transmission, real-time synchronization, and system integration, failing to effectively merge with personnel positioning systems and creating operational challenges for safety management. Therefore, achieving real-time, accurate detection of five key gases alongside wireless data transmission and system integration is not merely about stacking devices—it is a core requirement for fortifying personnel safety defenses.

For the client's IoT system service provider, the core objective is to build an integrated “personnel positioning + gas monitoring” safety management system for the shipyard. The practical value of this system hinges on the precision of gas detection data and the stability of its transmission—it must simultaneously monitor five gases, adapt to complex working conditions, enable real-time wireless data uploads, and seamlessly integrate with existing positioning systems to provide timely basis for safety decisions. This urgent demand for “multi-component detection + wireless transmission + system integration” calls for a professionally tailored gas detection solution.

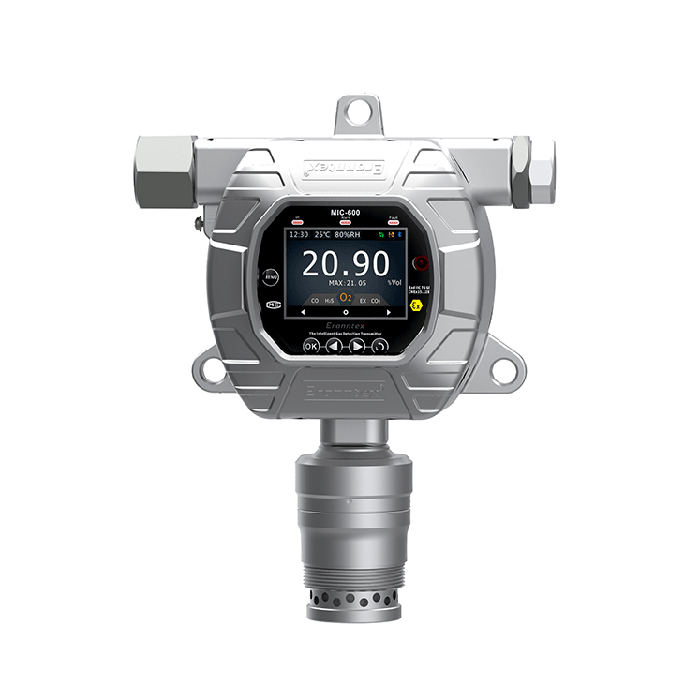

Against this backdrop, the Yiyuntian Eranntex MIC-600-S-5 Five-in-One Gas Detector with 433MHz wireless module emerged as the answer. It carries high expectations as the key device to help clients enhance their personnel positioning systems and safeguard confined space operations in shipyards.

I. Solution Background

The client is a shipyard in Shanghai requiring confined space gas detection.

The inquiring customer, an IoT system provider specializing in personnel location systems, aims to integrate our device into their system. The project requires battery-powered, five-in-one detection of CO₂, O₂, VOC, CH₄, and H₂S.

II. Parameter Requirements

Detect CO₂/O₂/VOC/CH₄/H₂S in a single unit, battery-powered, with data transmitted to client receivers via 433MHz wireless communication.

III. Solution

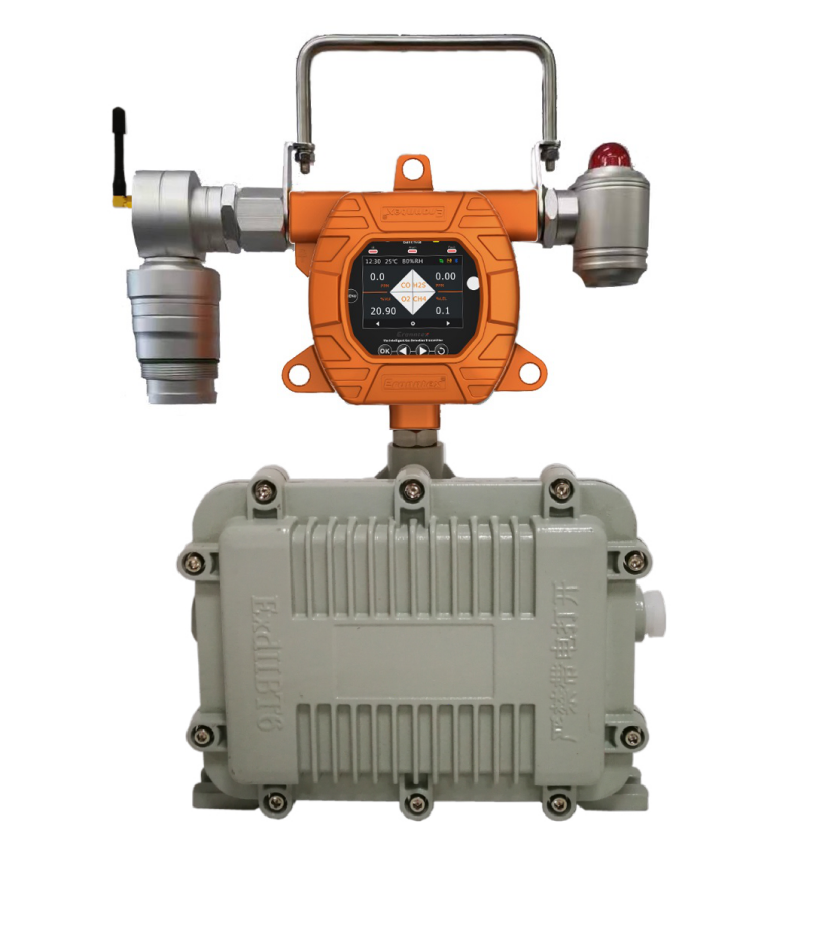

Wireless portable five-in-one gas detector MIC-600-S-5 (CO2/O2/VOC/CH4/H2S) + 433MHz wireless module to achieve detection and wireless transmission functions.

IV. Matched Products

MIC-600-S-5 (CO2/O2/VOC/CH4/H2S) + 433MHz wireless module

Detection Range: CH₄: 0-100% LEL, 0.1% LEL

Detection Range: H₂S: 0-100 ppm, Resolution: 0.01 ppm

Detection Range: O₂: 0-30% vol, Resolution: 0.01% vol

Detection Range: CO2: 0-2000PPM, Resolution 1PPM

Detection Range: VOC: 0-20000PPM, 1PPM

Includes 433MHz wireless data transmission module

With the widespread deployment and stable operation of the Yiyuntian Eranntex MIC-600-S-5 five-in-one gas detector equipped with a 433MHz wireless module in confined space operations at a certain shipyard in Shanghai, the shipyard has achieved a dual leap in both safety management standards and operational efficiency. This detection system establishes a robust safety barrier for confined space operations through its five-in-one multi-component precision detection capability, battery-powered portability, and stable wireless transmission performance, serving as a “data sentinel” safeguarding workers' lives.

The implementation of this detection solution not only enables the shipyard to monitor critical gas concentration data in confined spaces in real time, providing precise basis for operational safety decisions, but also positions the enterprise at the forefront of safety management planning. By integrating gas data with personnel positioning systems, the shipyard successfully mitigates potential gas hazards in confined spaces. This approach not only safeguards workers but also enhances production workflow efficiency. It bolsters confidence in tackling complex operational safety challenges while setting a benchmark for safety management in the shipbuilding industry.

For the IoT system provider, this collaboration marks a pivotal step in upgrading its personnel positioning system from “single-function tracking” to “safety-linked operations” and “intelligent prevention and control,” significantly boosting its market competitiveness in industrial safety IoT. For Yiyuntian Eranntex, this represents not only a successful integration of gas detection equipment but also a significant practice in the field of “integrated industrial safety monitoring.” It further demonstrates that Yiyuntian Eranntex gas detection technology not only meets standalone detection requirements but also deeply integrates into IoT system scenarios, playing a core, interconnected role within complex industrial safety protection systems.

Looking ahead,Yiyuntian Eranntex will continue to uphold its corporate mission of “Safeguarding Safety Through Technology.” We will deepen our expertise in multi-component gas detection and wireless transmission technologies while exploring deeper integration between gas detection equipment and systems like personnel positioning and emergency response. Simultaneously, it will actively expand applications across confined space operations in chemical, municipal, construction, and other sectors. By collaborating with industry partners, it aims to empower safe production through technology, building impenetrable industrial safety barriers to safeguard the lives and safety of every worker.

Related information

-

Failing compliance inspections? Yiyuntian Eranntex oxygen detectors ensure traceable data for enhanced compliance.

Amidst rising consumer expectations, demands for food freshness and safety have grown increasingly stringent. As a critical method...

2026-01-21 -

Yiyuntian Eranntex Wireless Integrated Gas Detection Solution Emerges as New Choice for Confined Space Protection!

Confined spaces are enclosed with poor ventilation, prone to accumulating gases like carbon dioxide and methane. They may also exp...

2026-01-20 -

Constantly worried about gas hazards in your chemical plant? Yiyuntian Eranntex Weather gas detectors make safety visible!

Against this backdrop, Yiyuntian Eranntex Weather gas detectors establish an intelligent protection network spanning the entire “...

2026-01-19 -

Yiyuntian Eranntex Valve Well Leak Detection Equipment Enables “Visible, Early Warning” Leak Monitoring for Urban Gas Pipelines

Urban gas pipeline networks serve as critical infrastructure for energy distribution, providing essential power to households, bus...

2025-12-15 -

Yiyuntian Eranntex Odor Online Monitoring System Emerges as a New Powerhouse for Environmental Enterprises

Within the modern framework of harmonizing industrial production with ecological conservation, workshop safety and environmental q...

2025-12-12

info@eranntexgas.com

info@eranntexgas.com

13480931872

13480931872