Failing compliance inspections? Yiyuntian Eranntex oxygen detectors ensure traceable data for enhanced compliance.

Amidst rising consumer expectations, demands for food freshness and safety have grown increasingly stringent. As a critical method for extending shelf life, nitrogen-flushing technology in food packaging has become a top priority for quality control in the food industry. Substandard nitrogen concentrations directly cause food oxidation, spoilage, and microbial growth—damaging brand reputation while creating potential food safety hazards. Simultaneously, regulators increasingly mandate traceability throughout production, making documented testing records a mandatory requirement for compliant operations.

However, the unique structure of small food packaging poses challenges for gas concentration detection. These bags are compact with limited internal gas volume. According to food industry standards, residual oxygen detectors must be strictly controlled below 5% vol after nitrogen filling to ensure product quality stability throughout the shelf life. During mass production, companies must rapidly and accurately detect gas concentrations in each batch while fully preserving testing data to meet regulatory sampling and quality traceability requirements.

However, traditional pump-based detection equipment exhibits significant technical limitations when testing small packaging bags. Due to the minimal gas volume inside the bags, pump-based devices rapidly evacuate the contents upon activation. Before detection data stabilizes, the gas is completely depleted, leading to distorted results. This makes it difficult for companies to accurately determine product compliance, potentially allowing non-compliant items to enter the market. Furthermore, some traditional devices lack automatic data storage, requiring manual recording of results. This approach is inefficient and prone to data omissions or recording errors, failing to meet modern production requirements for compliance and precision management.

Against this backdrop, to comprehensively address this industry challenge, Yiyuntian Eranntex leveraged in-depth research into food packaging inspection scenarios and its technical expertise in gas detection to introduce a targeted solution.

1. Solution Background

Requirement: Capable of detecting gas concentration within small food packaging bags while enabling data archiving to ensure gas levels meet packaging specifications.

2. Solution

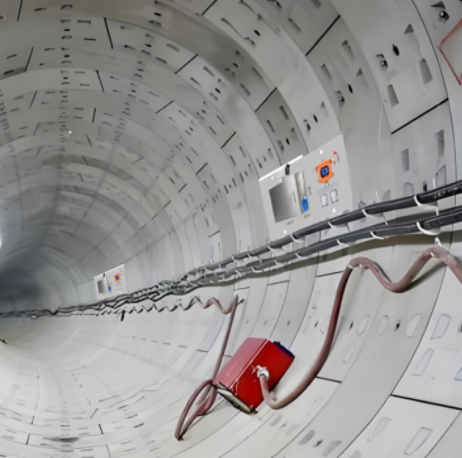

Conventional pump-based detection methods cannot accurately measure gas concentrations in small food packaging bags due to insufficient gas volume. Before detection data stabilizes, the bag's gas is completely evacuated. To address this application scenario, our company employs a sampling detection method combining equipment with inlet and outlet needles. This creates a circulating gas flow path, ensuring sufficient gas volume for accurate detection.

3. Product Configuration

Ensures nitrogen concentration compliance by measuring oxygen levels

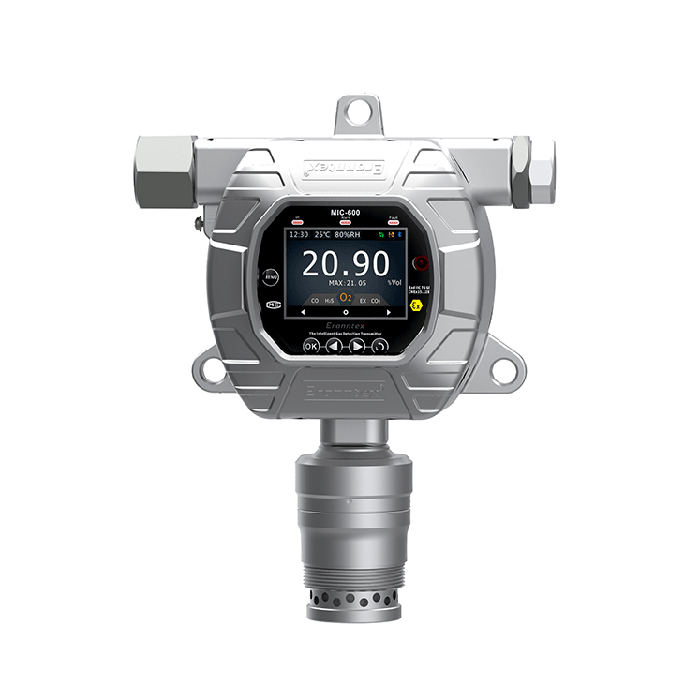

BTYQ-MS104K-L-O2-AW + Inlet needle adapter + Outlet needle adapter

Oxygen O2: Range 0-5% vol, imported electrochemical sensor

Can also detect other gases per customer requirements

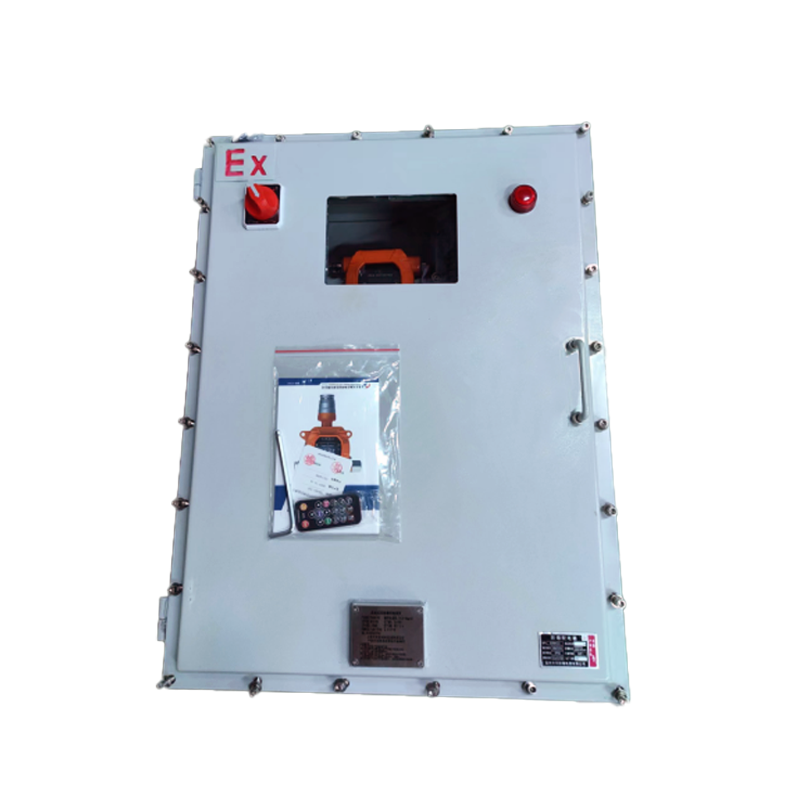

On-site installation diagram:

The core innovation of this solution introduced by Yiyuntian Eranntex lies in its recirculating gas flow path design. By coordinating the intake and exhaust needles, it enables the reuse of gases during testing. This ensures sufficient gas volume for detection while preventing damage to packaging bags, fundamentally resolving the inaccuracy issues inherent in traditional pump-suction detection methods. The paired BTYQ-MS104K-L-O2-AW oxygen detectors, equipped with an imported electrochemical sensor, delivers high-precision detection performance. Its 0-5% vol measurement range perfectly matches the oxygen residue testing requirements for small food packaging bags, ensuring accurate and reliable results.

Additionally, the device supports automatic data archiving, eliminating manual recording while ensuring complete storage of each batch's test data. This enables instant retrieval and review, enhancing quality traceability efficiency and effortlessly meeting compliance requirements. The solution also offers excellent flexibility, allowing expansion to detect other gases based on customer needs. It adapts to various food packaging scenarios, further broadening its application scope.

Since its market launch, this solution has successfully served enterprises across multiple sectors including snack foods, prepared foods, and nuts/dried goods. Its precise detection performance, user-friendly operation, and comprehensive data management capabilities have earned widespread customer recognition.

The successful implementation of Yiyuntian Eranntex Nitrogen Detection Solution for Small Food Packaging not only provides food enterprises with an efficient and accurate testing tool but also advances quality control standards within the food packaging industry. Moving forward, Yiyun Tian will continue to focus on addressing industry pain points by increasing R&D investment, optimizing product performance and solutions, and enhancing equipment intelligence and portability—such as adding wireless data upload and batch testing capabilities. Through technological innovation, we will empower the food industry's high-quality development and fortify the first line of defense for consumer food safety.

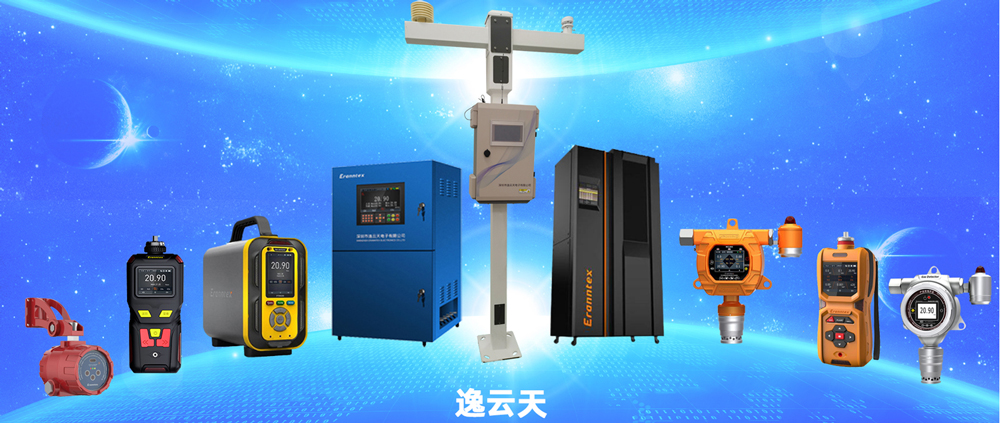

Related information

-

Failing compliance inspections? Yiyuntian Eranntex oxygen detectors ensure traceable data for enhanced compliance.

Amidst rising consumer expectations, demands for food freshness and safety have grown increasingly stringent. As a critical method...

2026-01-21 -

Yiyuntian Eranntex Wireless Integrated Gas Detection Solution Emerges as New Choice for Confined Space Protection!

Confined spaces are enclosed with poor ventilation, prone to accumulating gases like carbon dioxide and methane. They may also exp...

2026-01-20 -

Constantly worried about gas hazards in your chemical plant? Yiyuntian Eranntex Weather gas detectors make safety visible!

Against this backdrop, Yiyuntian Eranntex Weather gas detectors establish an intelligent protection network spanning the entire “...

2026-01-19 -

Yiyuntian Eranntex Valve Well Leak Detection Equipment Enables “Visible, Early Warning” Leak Monitoring for Urban Gas Pipelines

Urban gas pipeline networks serve as critical infrastructure for energy distribution, providing essential power to households, bus...

2025-12-15 -

Yiyuntian Eranntex Odor Online Monitoring System Emerges as a New Powerhouse for Environmental Enterprises

Within the modern framework of harmonizing industrial production with ecological conservation, workshop safety and environmental q...

2025-12-12

info@eranntexgas.com

info@eranntexgas.com

13480931872

13480931872